Measuring microwave material dielectric properties since 1996.

What We Do

What We Do

MPN measures microwave material dielectric properties

- from 50 MHz to 3000 MHz

- under process conditions

- to your desired temperature ( up to 1400°C )

- in your choice of gas atmosphere

What clients say

What clients say

Our measurements can reduce your development costs by answering these crucial questions :

- Will my material heat well in a microwave field?

- What is the best choice of frequency for heating/processing my material?

- What type and geometry of applicator is best suited to processing my material?

- How uniform will the heating of the work piece be at processing temperatures?

- Will its microwave absorption characteristics change during the processing?

- Will thermal runaway be a problem in my microwave processing system?

- Does my thermal insulation absorb/reflect microwave power at high temperatures?

Our services include

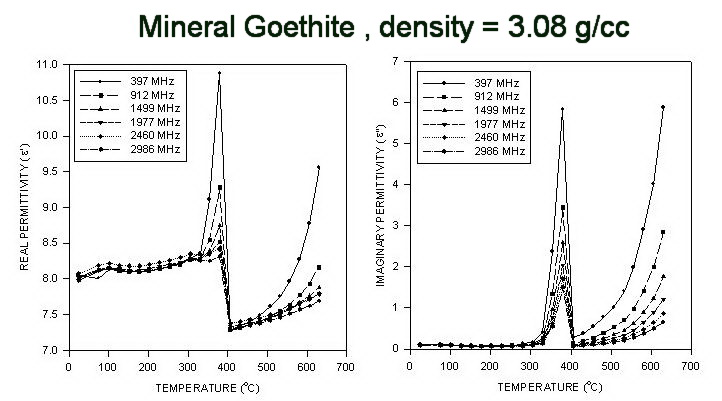

- Measurement of the complex dielectric constant of small samples, at frequencies between

50 MHz and 3000 MHz, up to high temperatures (-35°C to 1400°C), under specified industrial

processing conditions (pressure, cover gas, temperature, moisture content, temperature ramp

rate, density).

Measurement on ceramics, polymers, glasses, metal oxides, ferrites, liquids, organics, foods, fabrics, earthenware, minerals, biological samples, explosives, fuels ------ - Measurement of magnetic susceptibility (ie., complex permeability) between 900 MHz and 2800 MHz, up to high temperatures (-35°C to 1000°C) with either zero magnetic bias or perpendicular DC magnetic bias (up to 3 kGauss), done under specified processing conditions (pressure, temperature, moisture content, cover gas, temperature ramp rate, density)

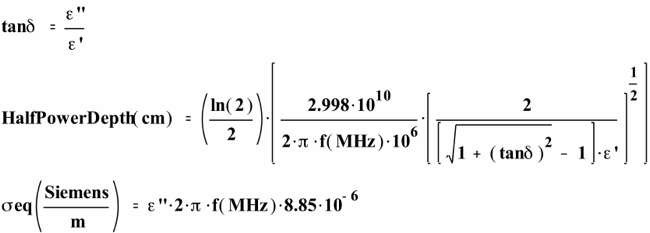

- Measurements of Rf and microwave attenuation coefficients, half-power depths, and reflection coefficients ( using small samples), to assist in detailed applicator design and interpretation of radar and satellite images

- Assisting with design of continuous flow and batch process applicators for industrial Rf and microwave heating

- Scoping calculations of microwave heating rates and heating distributions for process simulation, including time dependent and thermal runaway effects - used for microwave process feasibility studies

Our customers

Our customers have included many groups working at the forefront of developing innovative microwave-based industrial processes or new materials for microwave system applications, such as Dow-Corning, Owens-Corning, PEPSICO, Saint Gobain, Schlumberger, SUNCOR, GE Research, Kimberly Clark, SCHOTT Glas, Geological Survey of Canada, Ceradyne, Cameco Corp., Sherrit Inc., NRCAN, Rio Tinto ….

We have also done collaborative work with several university groups, including Prof. David Clark, Materials Science & Engineering, Virginia Tech, Prof. Chris Pickles, Queens` University Mining Engineering, Prof. Jason Zhang, Dept. Chem. Eng., Univ. of Ottawa Prof. Jiann-Yang Hwang , Michigan Technological University