The Dielectric Properties of Some Ceramic Glazes Known to Heat in a Home Microwave Oven

R. Hutcheon and J. Mouris , MPN, Deep River, ON, Canada, K0J1P0

J. Sankey, Ottawa, ON, Canada

1) Introduction :

Eva Gallagher and Mike Milgram, of the Deep River Potters Guild, had provided MPN with unfired clay samples, on which measurements of the basic microwave dielectric properties were done, as a function of temperature, during a firing cycle, with a view to understanding possible firing in a home microwave oven. After hearing of this, some of their associates mentioned that specific microwave-absorbing glazes had been identified, and suggested that dielectric property measurements might help with understanding the reasons for the microwave absorption. John Sankey sent MPN four tile samples of fired, glazed clay. His experiments with a home microwave oven had suggested very little heating of the basic clay backing material, while the glazed ceramic tiles heated readily.

When the samples arrived at MPN, the DC conductivity of the glaze on the samples was checked with a sensitive ohm-meter, and DC resistances of greater than many megohms were noted using a probe spacing of one millimeter on a glazed surface. This eliminates standard electron conductivity as a microwave heating mechanism near room temperature.

Next, a few very simple heating experiments were done by attempting to heat the glazed tiles in a Panasonic 1200 watt home microwave oven. Each sample was heated at full power for 10 seconds, after which the sample was quickly removed and the surface temperature of the glaze immediately measured using a 20 thou sheathed Type K thermocouple. This yielded only a crude indication of how well a glaze itself heated, because the final average sample temperature was strongly influenced by the glaze thickness. This is because the heat deposited in the glaze rapidly flows into the clay substrate ( they are in intimate contact!), meaning the heat was rapidly distributed through the whole sample. The thickest glaze ( OPT14) was the hottest!

To prepare for dielectric constant measurements, MPN diamond-sawed appropriate samples of two of the glazed-on-one-side ceramic tiles, and one sample of the “backing” or underlying clay ceramic. The third glaze ( OPT14 ) was so thick that it was removed from the backing and measured as a coarse powder.

Complex dielectric constant measurements were done during a cycle to 900ºC and back to room temperature, in air. The measured values for the glazed samples were compared with the backing measurements, and approximate values for the glaze material determined.

Since the source of the heating might also be magnetic properties ( microwave permeability), and since the OPT14 glaze sample did not have the confusion factor of having a backing, magnetic properties measurements were done on it. The magnetic absorption was essentially zero!

2) Sample Characteristics :

The MPN measurement system requires a sample that fit inside a 4 mm inside diameter (ID) “quartz” glass tube. The glazed ceramic tiles sent by John Sankey were diamondsawed to produce ~ 12 mm long, thin samples, with ~1 to 2 mm thickness of clay backing ( See photos). A piece of the underlying clay backing was also cut to a similar shape for a comparison measurement. The OPT14 material was too brittle to form a single solid sample, but the glaze was thick enough that it could be separated from the substrate.

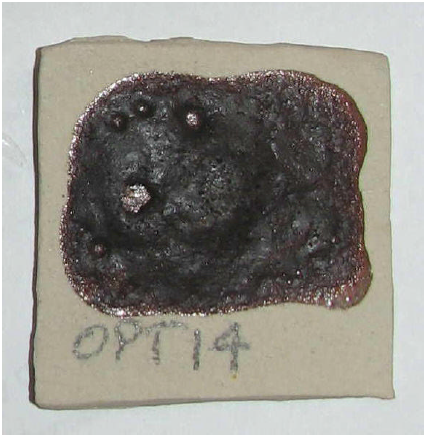

The following describes the preparation and firing sequence of the glazed samples, and includes pictures of the glazed tiles, along with a chemical analysis of the final fired glaze. John Sankey included the following comments with the samples:

3) Physical Properties of Dielectric Measurement Samples :

- a) Clay Backing (Substrate) Sample:

- Initial:

- --- length 12.16 mm

- --- width 2.93 mm

- --- thickness 2.12 mm

- --- mass 0.162 gm

- Final ( after measurement cycle to 900ºC): Unchanged .

- b) MgP Sample, Glaze + Substrate :

- Initial:

- --- length 12.17 mm

- --- width 2.9 mm

- --- thickness total ~ 2.45 mm (~ 1.5 mm backing, ~ 0.95 mm glaze)

- --- mass 0.190 gm

- Final Unchanged .

- c) OPT14 Sample :

- ----- The sample was a collection of reddish-brown glaze chips ( no substrate), and was unchanged in both mass and dimensions after the run.

- --- mass 0.150 gm

- --- height 13.57 mmm

- --- diameter 4.05 mm

- d) SIR Fe 20.8 Sample, Glaze + Substrate :

- Initial:

- --- length 12.35 mm

- --- width 3.11 mm

- --- thickness 1.86 mm, total glaze plus thin (~ 0.07 mm) substrate

- --- mass 0.153 gm

- Final Unchanged .

4) Dielectric Properties Measurement Run Specifications :

All samples were taken through the same temperature cycle, up to 900°C and back to room temperature, and the measurement system parameters were the same for all samples.

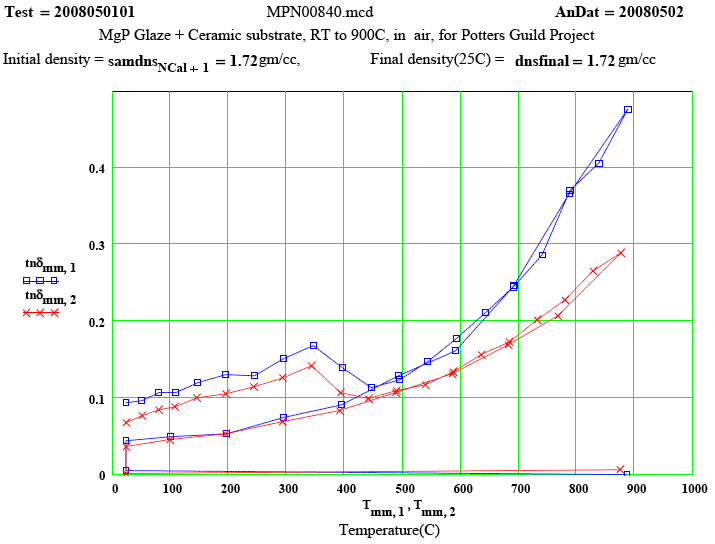

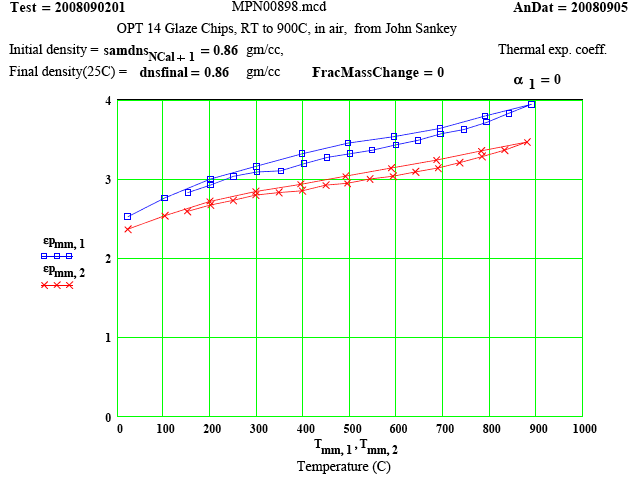

- --- Measurements at two frequencies, 912 ( blue squares) and 2466 MHz ( red crosses), the two frequencies were measured effectively simultaneously, ie., within 2 seconds of each other.

- --- The temperature sequence was: room temperature (RT) to 900°C, in ~50°C steps, then back down to RT in 100°C steps

- --- Atmosphere was air .

5) Presentation of Data and Discussion of Results:

The MPN system measures two quantities, the dielectric constant, ε', and the loss factor, ε" . Since the heating rate per unit volume of a simple sample in a microwave oven is crudely proportional to the ratio of these two quantities (ε"/ε' = tanδ ), the data is presented as plots of ε' and tanδ for each sample versus temperature.

Water is considered a very good microwave absorber. At 2450 MHz ( the home microwave frequency), water has values of tanδ ≈ 0.14 at room temperature, and tanδ ≈ 0.07 at 50°C . The measured values for the ceramics can be compared with these water values to give an intuitive estimate of the ceramics ability to be heated in a microwave oven.

However, because two of the present measurement samples are double-layered ( the glazes were too thin to separate from the substrate), the response produced by microwave absorption in these samples is the sum of that of the clay substrate and the thin glaze layer. The individual response of each layer depends on the product of (1) the layer thickness, (2) the ε" of the layer, and (3) the effective square of the electric field inside the layer. Thus, if the substrate has low microwave absorption, and the glaze large absorption, the measurements of the combined glaze and substrate will show only moderate absorption!

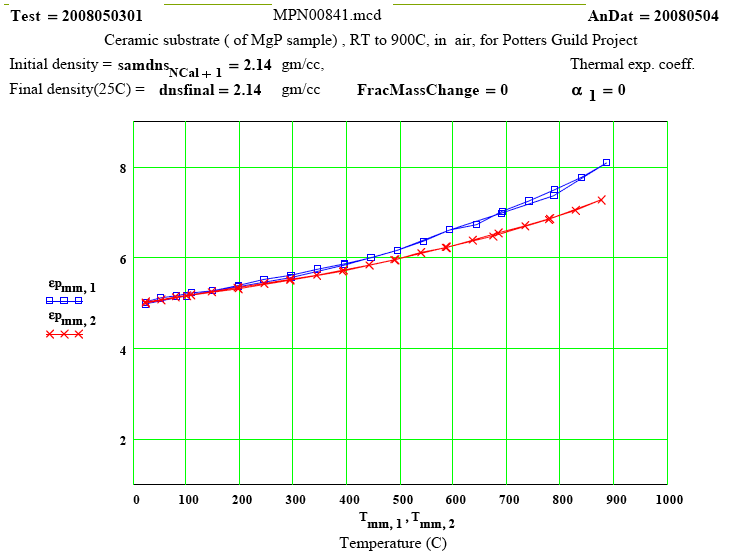

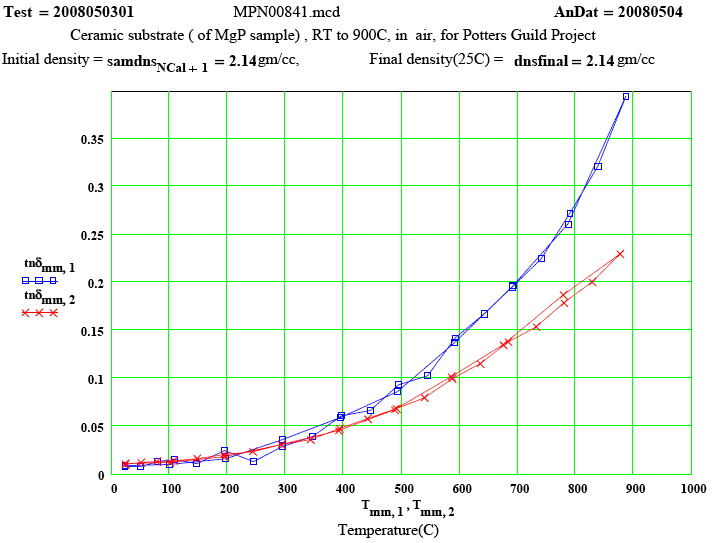

a) Clay Substrate Sample:

The following are the measured values of the real part of the dielectric constant, ε', and of tanδ for the clay substrate, during a cycle to 900ºC and back to room temperature. Clearly, the values are stable and reversible, and unchanged by the heating cycle. As well, there appear to be no phase transitions during the heat-up. The rapid increase of ε' with temperature suggests a low to moderately lossy ( or microwave absorptive) material, with the value of tanδ rising from ~ 0.01 at room temperature to ~ 0.05 at 400ºC.

The measured values of tanδ increase rapidly with temperature, suggesting the microwave absorption mechanism is thermally activated. Note that at 600ºC, the 2450 MHz value of tanδ is the same as that of room temperature water, meaning quite absorptive! However, the value at room temperature is quite low, and thus a thin piece of moderately air-cooled material does not heat significantly.

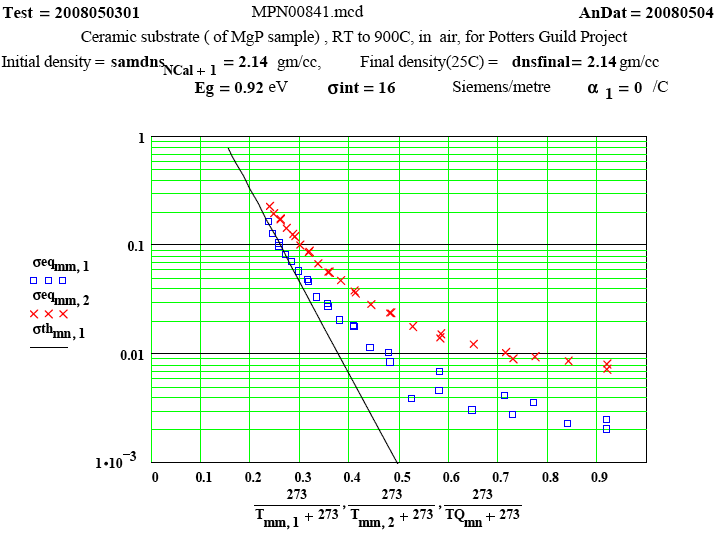

The Arrhenius plot of the equivalent electronic conductivity ( proportional to ε"* f ) suggests that above 1000ºC the dominant loss mechanism may be conduction electron conductivity, but that a lower temperatures, other mechanisms ( presumably ion conduction ) are active.

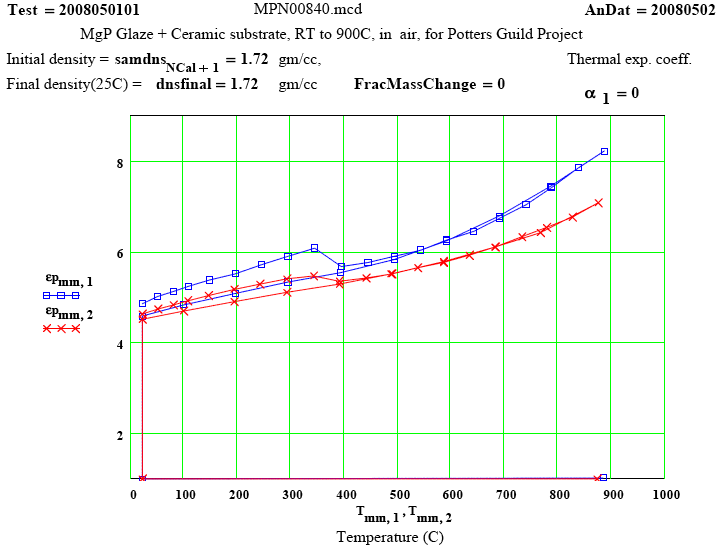

b) MgP Glaze on Clay Substrate:

The following are the measured average values of the real part of the dielectric constant, ε' and of tanδ for the MgP glaze plus substrate, during a cycle to 900ºC and back to room temperature. The values undergo a steep reduction between 350 and 450ºC on the heat-up part of the cycle, but this is not reversible on the cooldown! An irreversible phase transition must have occurred in the glaze material!

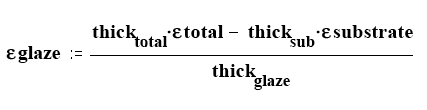

An approximate equation, derived using the long, thin sample shape approximation, was used to extract the specific glaze values, as a function of temperature, using the total measured combined sample value and the previously measured values for the substrate tile.

These plots are the extracted values, at ~ 2460 MHz, of the complex dielectric constant for the glaze on the MgP sample.

Clearly, an irreversible phase transition took place between 350 and 450ºC, but even after this, the glaze remains highly microwave absorptive (tanδ > 0.1) over the whole temperature range.

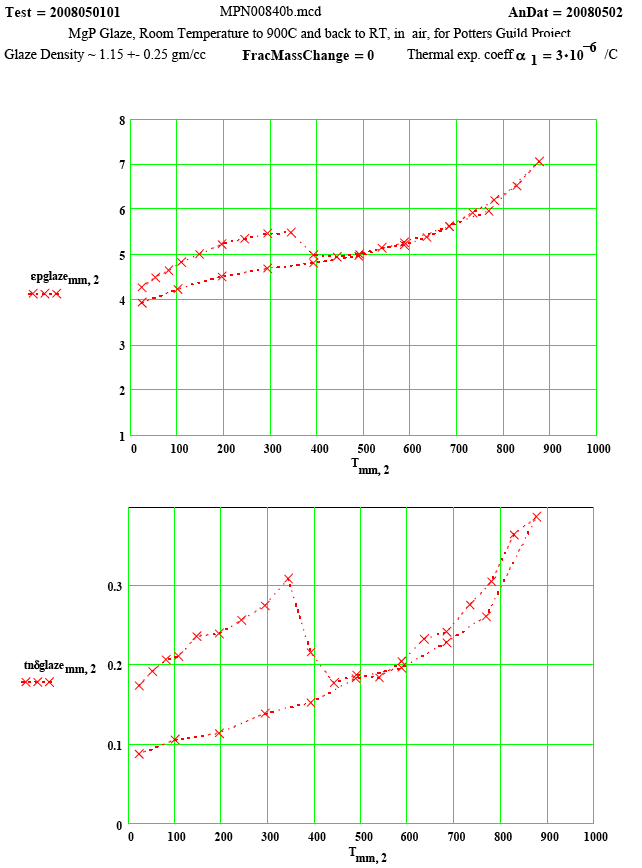

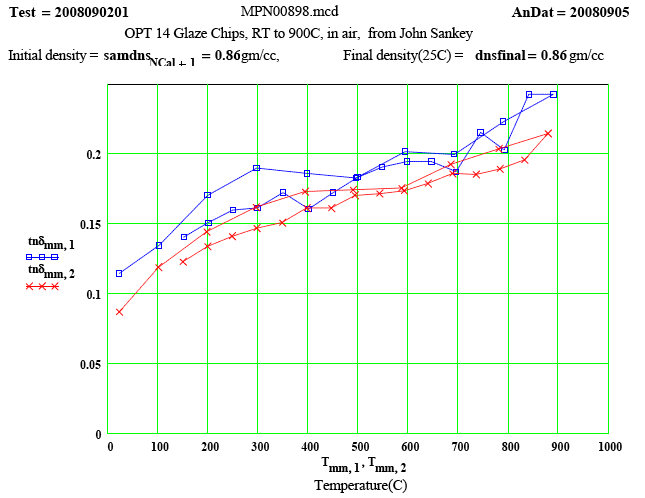

c) OPT14 Glaze Chips:

The following are the measured values of the real part of the dielectric constant, ε' and of tanδ for OPT14 glaze chips, during a cycle to 900ºC and back to room temperature. The values on heat-up and cool-down are essentially identical, suggesting no change in the glaze.

The room temperature values of tanδ are ~ 0.1 , and thus would result in efficient heating right from room temperature!

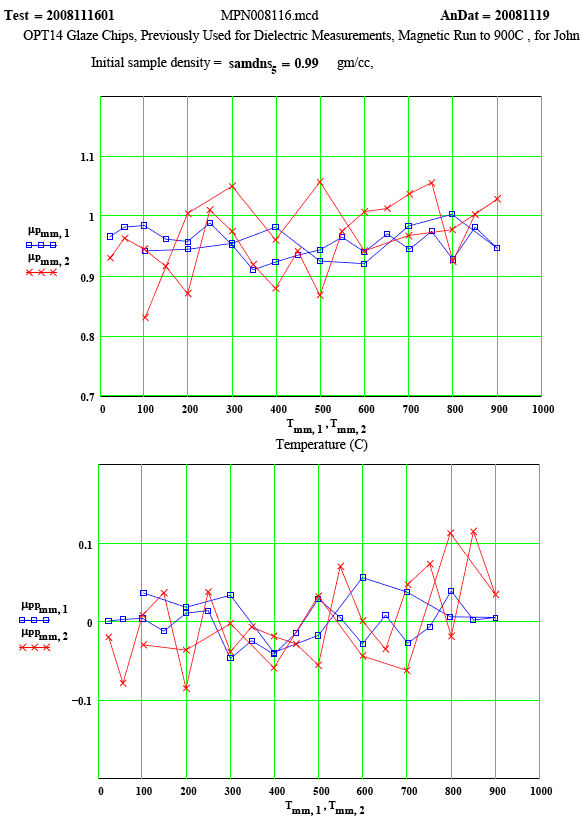

OPT14 Measurements ( Complex Microwave Permeability):

The following are the measured values of the real part of the permeability, μ' and of μ" for the same OPT14 glaze chips that were used for the dielectric property measurements, during a cycle to 900ºC and back to room temperature. The values on heat-up and cooldown are essentially identical, again suggesting no change in the glaze.

The room temperature value of μ" is very small, and shows no significant drop up to 900ºC, as would have been seen if the material went through a Curie Temperature transition. This, and the fact that μ' is essentially unity over the whole temperature range suggests the material has no magnetic structures in it!

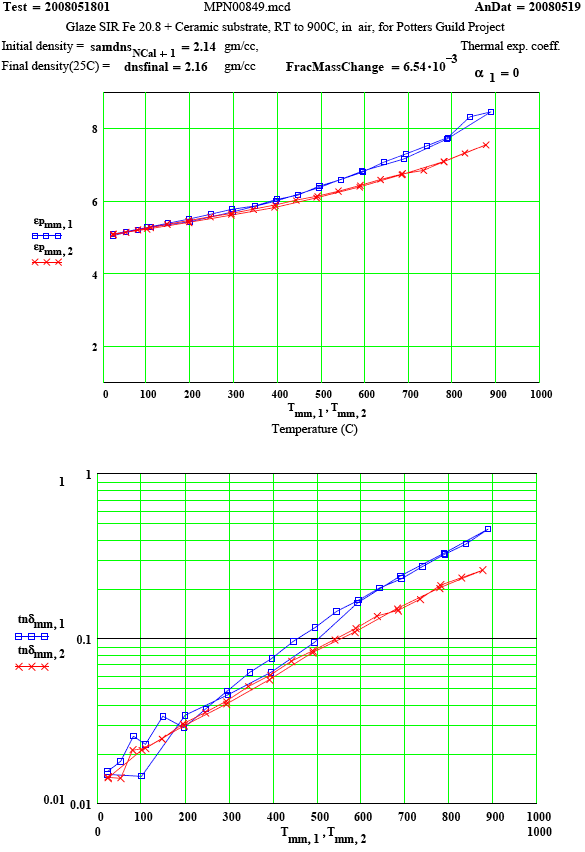

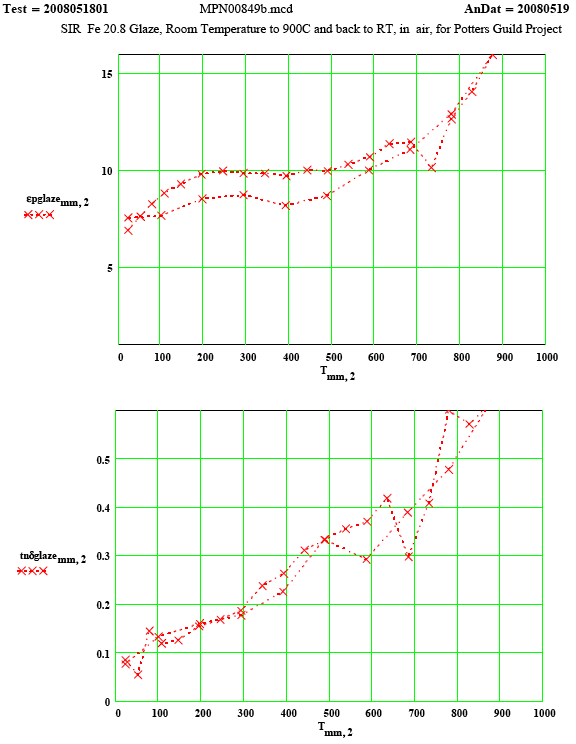

d) SIR Fe 20.8 Glaze + Substrate:

The following are the measured average values of the real part of the dielectric constant, ε' and of tanδ for the SIR Fe 20.8 glaze plus substrate, during a cycle to 900ºC and back to room temperature. The values on heat-up and cool-down are identical, suggesting no change in the glaze.

Again, the long, thin sample approximation was used to extract the values for the glaze from the combined measurement, assuming the substrate clay tile has the same response as previously measured. Note that here the values have large errors because the glaze was very thin, and it`s thickness not accurately determined! The values are for ~ 2465 MHz.

Again, although the errors are large, the room temperature values of tanδ are ~ 0.08, and increase rapidly with temperature, demonstrating that the glaze is quite absorptive and would heat readily!

6) Discussion of Results:

Clearly, these glazes will heat in a microwave oven, right from room temperature. The thickness of the glaze will determine the quantitative amount of heating of a glazed object, and surface cooling effects need to be taken into account for any quantitative work.

The glazes seem reversible, meaning they will retain their properties over temperature cycling.

The fundamental property of the glazes that make them absorb microwaves is yet to be determined. Plans for further measurements with different formulations, to determine the optimum formulation, are being made. Eventually, if glaze with optimum absorption is obtained, then basic x-ray analysis will be required to find which mineral or glass structure is responsible for the absorptive properties. This could be a long, slow, process, and the assistance of people with scientific knowledge of glazes and crystal and glass structures will be crucial.